Metal Parts Manufacturing

Metal parts manufacturing is a comprehensive manufacturing process. The process, which starts with laser cutting, is completed with a molding room, press shop, press brake bending, welding room, machining, and electrostatic powder painting method. Depending on the industry in which the metal part will be used and the mold characteristics, the manufacturing process varies. For example, while there is no need for press brakes in the production of some metal parts, machining is not required for some products. Therefore, the production of metal parts varies depending on the sector, industry, and the vehicle in which the part will be used.

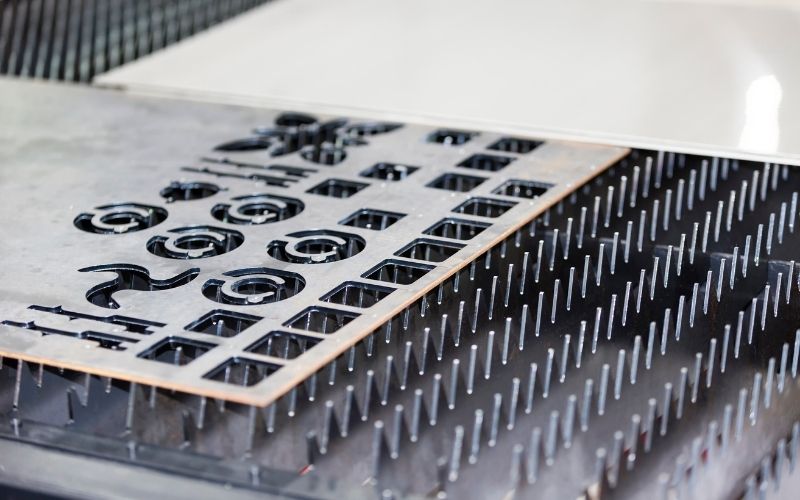

Production of Metal Parts with Laser Cutting

Metal forming is mainly done by laser cutting today. We produce stainless steel and plexiglass parts, especially sheet metal parts production. Also, we have a laser-cutting method suitable for all materials. We can examine the laser cutting methods used in metal parts production under 5 headings;

- CNC Laser Cutting

- CO2 Laser Cutting

- Fiber Laser Cutting

- Crystal Laser Cutting

- Metal Laser Cutting

You can contact us to get detail information about metal parts production costs.

Metal Parts Manufacturing in the Press Shop

We produce sheet metal parts for many sectors such as white goods, automotive, medical, machinery, electricity & electronics, lighting, heating and cooling, and aircraft industry, together with our eccentric press, mechanical press, and hydraulic press machines that we use in the press section. Our air clutch presses of 30 to 100 tons produce error-free high-speed special sensors. With our mass production techniques, we manage the drilling, bending, and shaping processes while doing laser cutting. In this way, we make sustainable mass production, and waste is minimal. Below you can see the metal parts that we produce on a sectoral basis;

- Automotive: Bellows parts, locking systems, engine parts, piston parts

- Machinery: Machine parts, machine spare parts, and components

- Medical: Prosthesis, wheelchair, dental technology, endoscopy/nanotechnology

- White Goods and Sanitary Ware: Plumbing fittings, valves, nuts, drum parts

- Electronics and Electricity: Energy distribution panels, control technology measurement systems

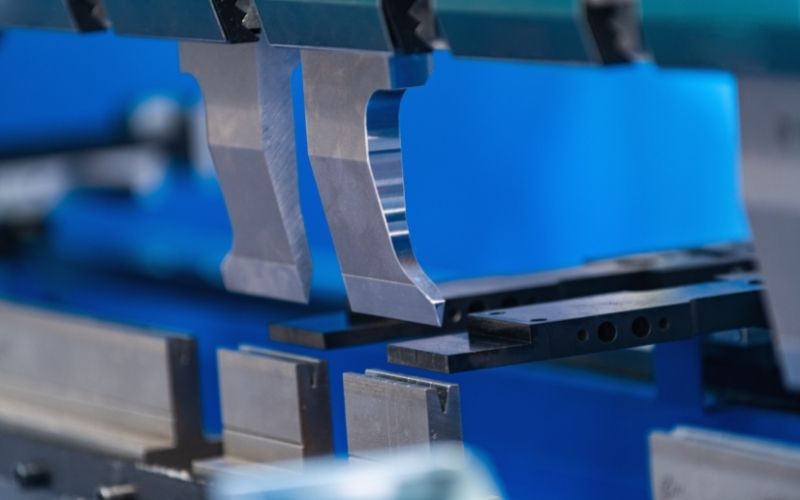

Metal Part Manufacturing with Press Brake

By applying the press brake bending technique at high temperature and pressure to sheet metal materials, we cause the material to bend. We produce parts of perfect quality with the codes such as twist rate and twist rate that we enter into our CNC machines. Below you can see the sectors where we apply the most frequent press brake bending.

- Airframes

- Automobile panels

- Metal artworks

- Sign making

- Steel manufacturing

- Kitchenware

- Pipe production

- Spare parts manufacturing

Metal Parts Production in the Welding Shop

After the laser cutting process, we weld the parts that need to be integrated into each other in our welding shop. We use argon welding, gas metal arc welding, and spot welding methods when welding. In our welding application, we can weld extensive parts and very small parts at the same time. We use it frequently because it is a very reliable method. We can weld sheet metal, stainless steel, and alloys.

Metal Parts Production with CNC Machining

CNC Machining is the metal part production technique in which we produce with the method of removing metal from the material. In this method we are using turning, milling, drilling, reaming, and grinding machines. The aim is to take the excess material on the metal part and give the material a geometric shape. We obtain completely clean and smooth surfaces with precise cuts. The sectors in which we apply machining are as follows;

- Energy sector

- Automotive industry

- Machinery Industry

- Manufacturing Industry

- Defense industry

- Railroad

- Metal production industry

- Elevator Industry

Metal Parts Manufacturing Companies

As Aktif Lazer, we push all the limits of technology to produce metal parts and we do laser cutting, press brake bending, machining, press, and welding. Please call us for detailed information about our production processes.